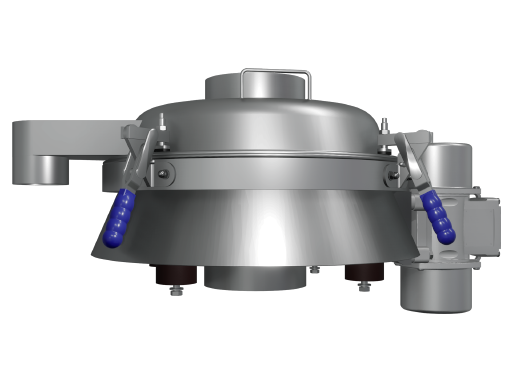

The Sievmaster Slimline Range of circular sieves feature a powerful vibratory motor, and a single mesh screen housed in a hygienically sealed, easy to clean, stainless steel sieve body.

A highly effective check screener available in four different diameters.

Designed to be gravity fed as part of a continuous production line or stand alone on mobile or static frames, these sieves are capable of handling both wet and dry applications.

Pneumatic lifting and lowering systems are available on larger models to increase ease of personnel interaction, reducing health and safety risks, and provide ample access to the mesh screen for inspections and removal for cleaning and mesh replacements.

For factories with limited room, different styles of vision inspection ports are offered.

Discover more about how our Slimline sieving products can help you. View the specification for this product here.

Download

Food & Drink

Pharmaceutical

Chemical

Additive Manufacturing

The Slimline Range can be used for processing a wide range of dry powdered / granular product or used for liquid separation. Slimline sieves are most used in the Food and Drink industries due to their hygienic design, making them equally suited for the Pharmaceutical and Chemical industries too.

The table below displays the specs for the Sievmaster Slimline Range of vibratory sieves. For further specs and information, please get in touch to find out more.

| SM 550 | SM 950 | SM 1250 | SM 1550 | |

| Max Throughput with 2mm mesh (product and mesh dependent) | 4,000 kg/h (8,800 lbs/h) | 12,400 kg/h (27,300 Ibs/h) | 16,800 kg/h (37,000 lbs/h) | 27,800 kg/h (61,300 lbs/h) |

| Screen Diameter | 565mm (22.2”) | 965mm (37.9”) | 1165mm (45.8”) | 1465mm (57.6”) |

| Standard Motor | 0.3 kW (0.4 HP) | 0.9 kW (1.2 HP) | 0.9 kW (1.2 HP) | 1.1 kW (1.5 HP) |

| Approx. Weight | 135 kg (298 Ibs) | 300 kg (661 Ibs) | 350 kg (772 Ibs) | 400 kg (882 Ibs) |

| Standard Finish | Internal: dull polish <0.8Ra External: satin finish <0.95Ra |

|||

| Typical Noise Level | <70dB (certificates available) | |||

| ATEX Rating (Internal & external) | Rated for ATEX zone 21 II 2D Unit can be upgraded to ATEX zone 20 II 1D (internal) and ATEX zone 22 II 3D (external). |

|||

| Contact Parts | 316 Stainless steel (1.4401) | |||

| Optional Certifications | 3.1 material, EAC, IECEx, and UL certificates. | |||

| Non-Contact Parts | 304 Stainless Steel (1.4301) | |||

| Country of Design | United Kingdom | |||

| Country of Manufacture | United Kingdom | |||

Request a quote

Whether it’s spares for a machine or a quote for new equipment speak to our sales team on +44 (0)1256 474 547