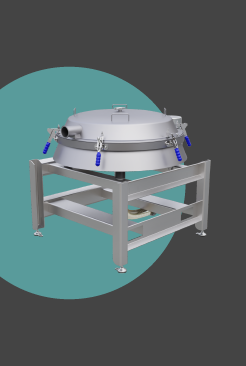

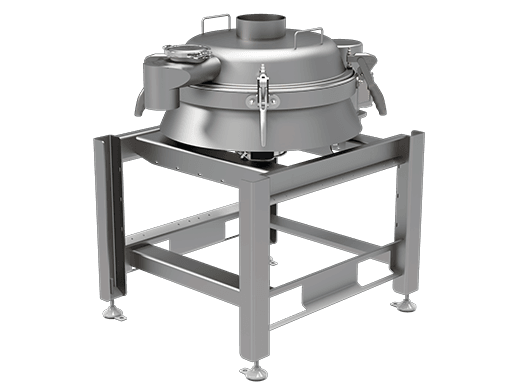

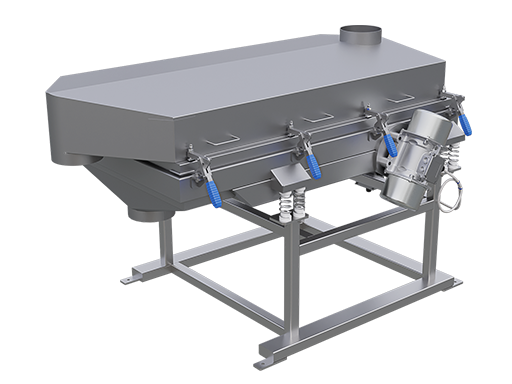

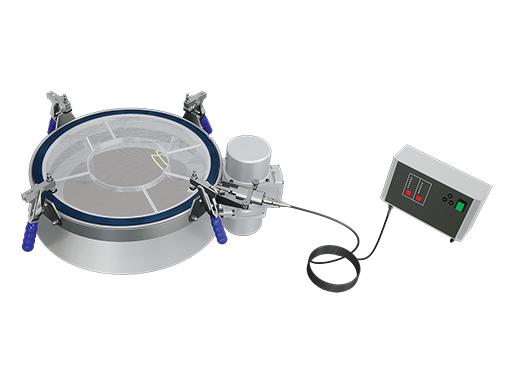

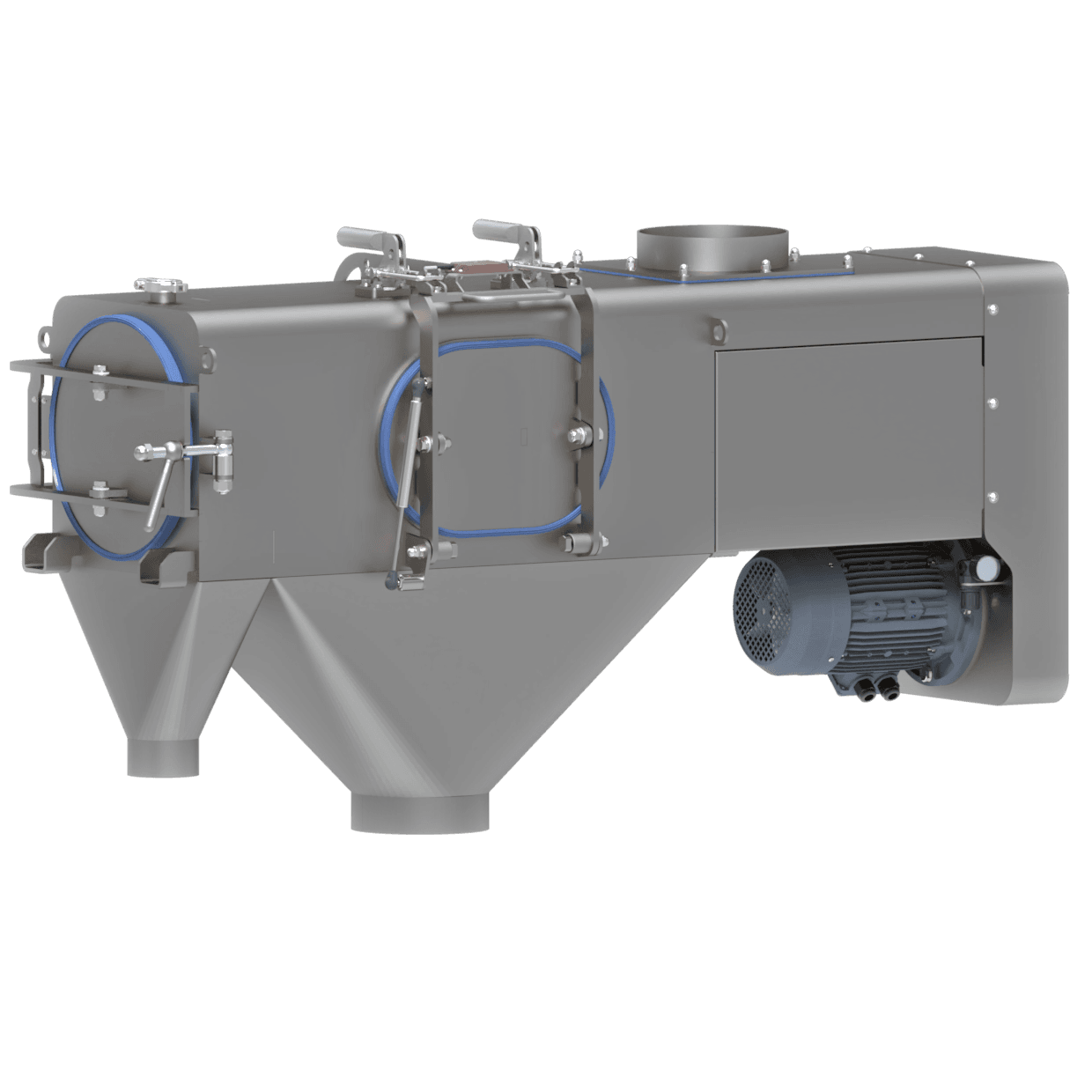

What is the Sievmaster Vacusiev?

To overcome the issue of dust generated from airborne powders, Farleygreene developed the Vacusiev range.

A range of vibratory check screeners designed to convey product safely from one area to another in a single operation. The flexible hose system and sieve are connected under vacuum to retain the product within, protecting both the operator and surrounding atmosphere.

These sieves are suited for check screening toxic, very fine, or dusty material; the larger 950 and 1250 models can be used within a pressure transfer system as well as under vacuum.