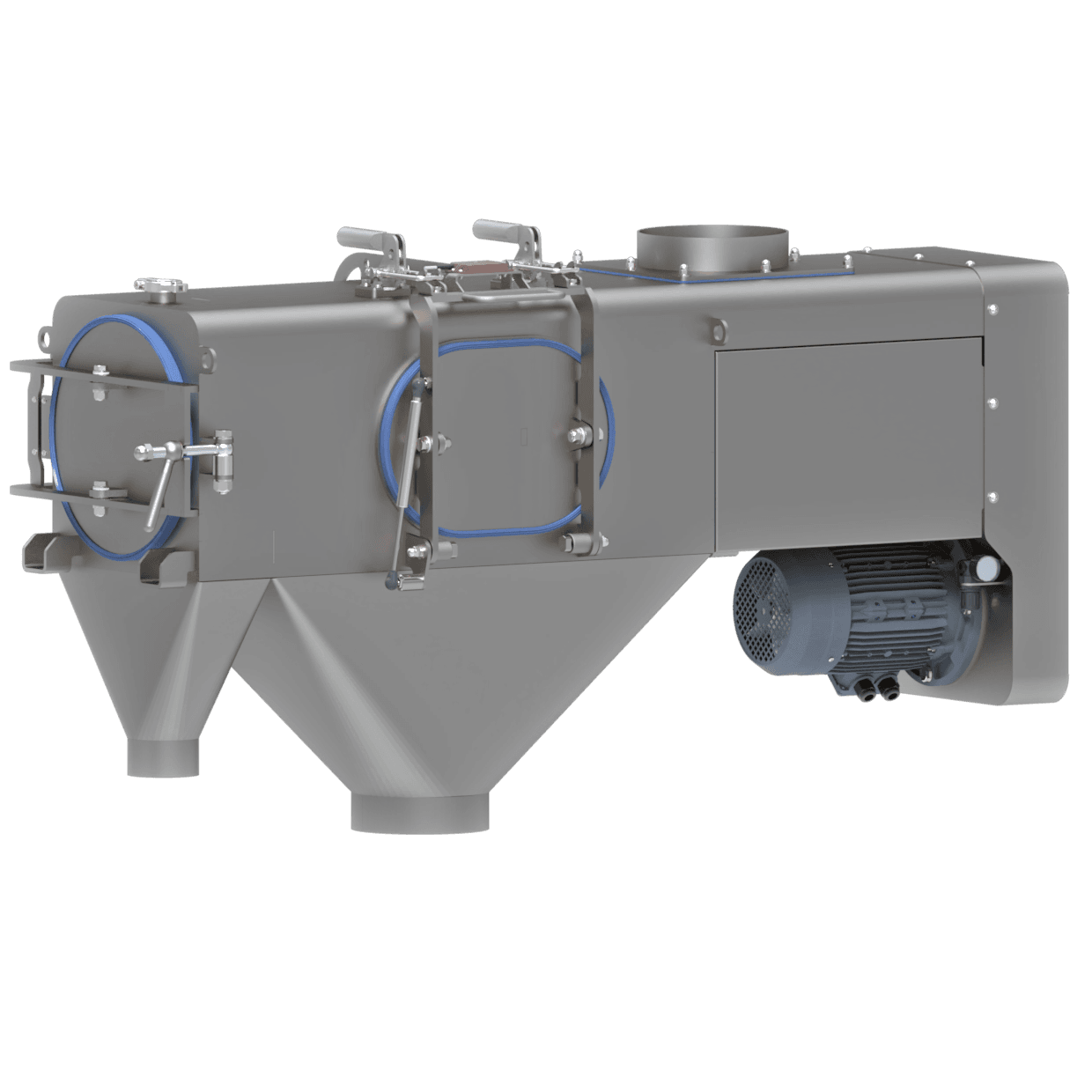

What is the Sievmaster Rota Sieve?

Where high volume bulk check screening is required, the Rota Range provides non-vibratory centrifugal sifting.

Rota sifters use a set of revolving paddles to push product outwards against the mesh cylinder, forcing fine product through and continuously ejecting coarse product via a separate outlet.

Rotas are dust tight and can be fixed into place within your process line.

The internal mesh screen assembly and sieving paddle components are fully removable without the need for any tools. The mesh can also be fully inspected across its full circumference and length whilst still in place inside the machine.